Facility & Equipment

-

Facility

Manufacturing: 35,000 sq. ft.

Office space: 3,000 sq. ft.

-

Frontline - Insight

Expedite Design analysis and quoting

-

Maskless Direct Imaging

Direct Imaging Technology since 2013

Use for all circuit imaging and available for soldermask

Resolution down to 2 MIL trace and space

-

PAL Automated Pulse Plating

Installed in 2022

Pulse plating for aspect ratio up to 20:1

Heavy copper plating available

In-line Microvia Fill (Coming soon in 2023!)

Automated dosing for steady state process control

Semi-automated daily analysis using Metrohm Professional CVS 894

-

Pluritec Inspecta HPL S2 Plus X-Ray Drill and Router with Vision

Optimize drill position after lamination for multilayer boards

Control Depth Drill and Rout

Layer analysis for improved stack-up yields

-

Mass VHF 200 and Wise Cleverstar

Conductive or non-conductive Via fill in accordance with IPC 6012 Class 3

Controlled planarization to minimize surface variation after paste removal

-

IPS Strip - Etch - Strip

2 MIL Trace and Space

3 MIL Cores Handling

Automated dosing for steady state process control

-

IPS Deep Gold Line

Allows processing of selective hard gold on full production panel, not just gold fingers

-

Pluritec Ecospray

Spray solder mask application with conveyorized tack-dry

Flexible colours: Green, Blue, Black, Red, White, Purple, Orange, Transparent

Easily coat any thickness of board

-

Microcraft JetPrint Direct Legend Printer

Digital ident printing (white)

-

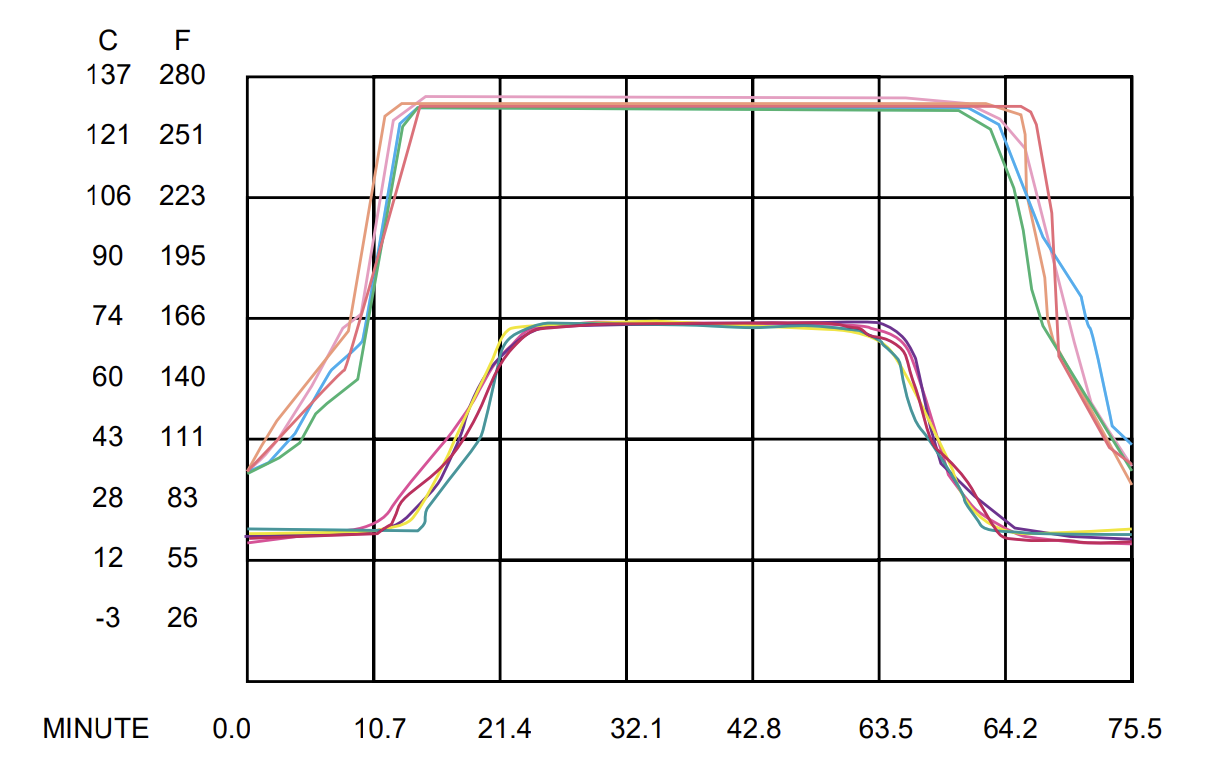

TC-120 Automated Oven

Conveyorized Oven for consistent curing of solder mask

-

IPS Electroless Nickel Immersion Gold (ENIG)

Semi-automated ENIG plating